Leading Waterjet Cutting Company In The South East - Serving The UK

"We offer precise, high-quality cutting"

— Neil Johns, MD

Do You Require Precision Cutting For Your Project?

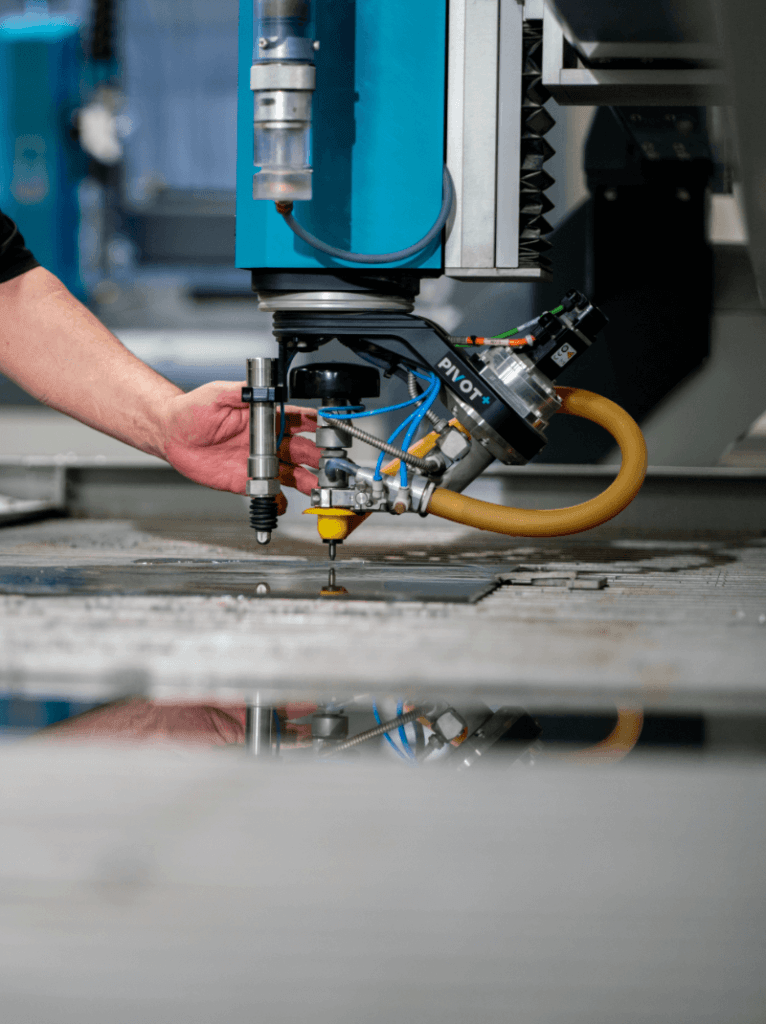

At Premier Waterjet Cutting our team of UK-based experts fully understand that your projects can require materials that are cut to extremely small levels of precision which is why our standard and abrasive waterjet cutting service is tailored to fully suit the needs of our clients. Contact us today to get your free quote.

Automotive & F1

Architecture & Design

Construction

Aerospace

The perfect solution for a wide range of industries in the UK

The Benefits Of Working With Our Experts

- Precise & Accurate Cutting

- Suitable For Dense & Hard Materials

- Fast Turnaround

- Cost Effective

- Tailored Service

- Transparent Communication

What Our Clients Say

Trustindex verifies that the original source of the review is Google. Incredible service would absolutely use these guys again THANK YOU Paul and the team!Trustindex verifies that the original source of the review is Google. Premier's water jet services are outstanding! They delivered precise and efficient results, using high-quality equipment and a skilled team. The project was completed on time and exceeded our expectations in terms of both quality and professionalism. Their attention to detail and commitment to customer satisfaction made the entire experience seamless. Highly recommend Premier for any water jet cutting needs!Trustindex verifies that the original source of the review is Google. At last, a quality waterjet cutting business in Essex. Thoroughly recommended.Trustindex verifies that the original source of the review is Google. Top notch service, efficient and friendly team. 10/10!Verified by TrustindexTrustindex verified badge is the Universal Symbol of Trust. Only the greatest companies can get the verified badge who has a review score above 4.5, based on customer reviews over the past 12 months. Read more

Our cutting bed is an impressive 4 metres by 2 metres

Bespoke Waterjet Cutting For UK-Based Companies

Utilising the latest technology for unparalleled efficiency and accuracy.

01. Initial Consultation

02. Recommended Solution

03. Material Cutting

04. Final Handover

05. Enjoy Your Materials

Our Services

Unmatched Quality

Cutting Through Anything, But Not Limitations:

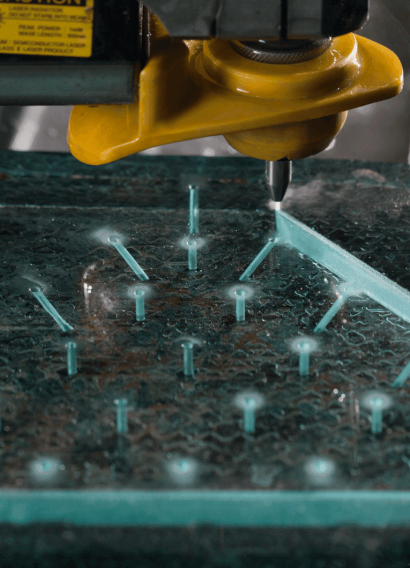

Abrasive waterjet cutting offers unparalleled versatility, capable of tackling virtually any material with the exception of toughened glass. Our cold cutting process eliminates the risk of heat distortion, making it ideal for metals and other sensitive materials.

This results in a smooth, burr-free finish and a precision unmatched by traditional cutting methods.

Our advanced waterjet machines can handle a wide range of materials with exceptional accuracy ( +/- 0.01mm), including:

- Acrylic

- Aluminium

- Brass

- Bronze

- Carbon Fibre

- Ceramics

- Composites

- Copper

- Plastics

- Steel

- Stainless Steel

- Titanium

- Wood

- Foam

- Kevlar

- Glass

With Premier Waterjet Cutting, you can rely on the ultimate solution for precise, efficient, and versatile material cutting.

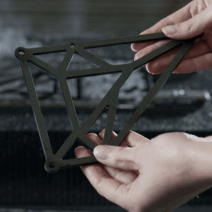

Automotive & F1: Precision cutting for complex components and prototypes.

Architecture & Design: Detailed, intricate cuts for architectural features and models.

Construction: Accurate cutting for structural components, panels, and custom designs.

Aerospace: Precision cutting for aerospace parts and components.

Film & Entertainment: Custom cutting for set pieces, props, and special effects.

Experience the Premier Waterjet Cutting difference. Contact us today for a consultation and let us bring your vision to life.

Why choose Premier Waterjet Cutting?

- Unmatched Precision: Achieve intricate details and complex shapes with +/- 0.01mm accuracy, thanks to our high-pressure waterjet technology.

- Versatile Cutting: Cut through virtually any material up to 200mm thick, from metals and plastics to composites and ceramics, with or without abrasives.

- Environmentally Friendly: Our cold process leaves no heat-affected zone and produces no harmful by-products, making it a sustainable choice.

- Superior Quality: Our ISO 9001:2015 certified services guarantee quality, leaving you with clean, burr-free cuts requiring minimal secondary finishing.

Ready to explore the possibilities of waterjet cutting?

We've compiled answers to some common questions to help you get started.

How accurate is waterjet cutting?

Our waterjet cutting machines deliver exceptional accuracy, achieving tolerances of just 0.1mm. This precision sets us apart and allows us to deliver results that meet even the most demanding specifications

How thick can you cut?

Our high-powered machines, operating at 60,000psi, can cut through virtually any material up to 200mm thick.

Can you cut angled components?

Absolutely! Our machine features a tilting cutting head, allowing us to create complex 3D parts with angles up to 60 degrees.

Do you work with small operations?

We understand the challenges faced by smaller businesses, and we’re committed to providing exceptional service to companies of all sizes. We’ve worked with both small startups and multi-national corporations alike.

What is your turnaround time?

Once your drawings are finalised and ready for cutting, our typical turnaround time is 3-4 days. We also offer overnight shipping for urgent projects.

What Is Abrasive Waterjet Cutting?

Abrasive waterjet cutting is a process that uses a high-pressure stream of water mixed with fine abrasive particles such as glass or metal to cut through various materials that are high dense.

Why choose waterjet cutting in the UK over other methods like laser or plasma?

Waterjet cutting for businesses in the UK offers high-precision cold cutting with no heat-affected zones, making it suitable for intricate components used in aerospace, automotive, and construction. It’s also more versatile with material thickness and types.

Where To Find Us

Have questions?

Get in touch!

Don't hesitate to contact us! We're happy to address any questions or concerns you

may have.