Our Bespoke Shot Blasting Services In Essex

Our experts support engineering, manufacturing and construction companies in Essex by providing their bespoke shot blasting services which ensures that your materials are durable, treatment ready and aesthetically pleasing. Request your free quote to understand how we can help you.

Why Shot Blast Your Materials?

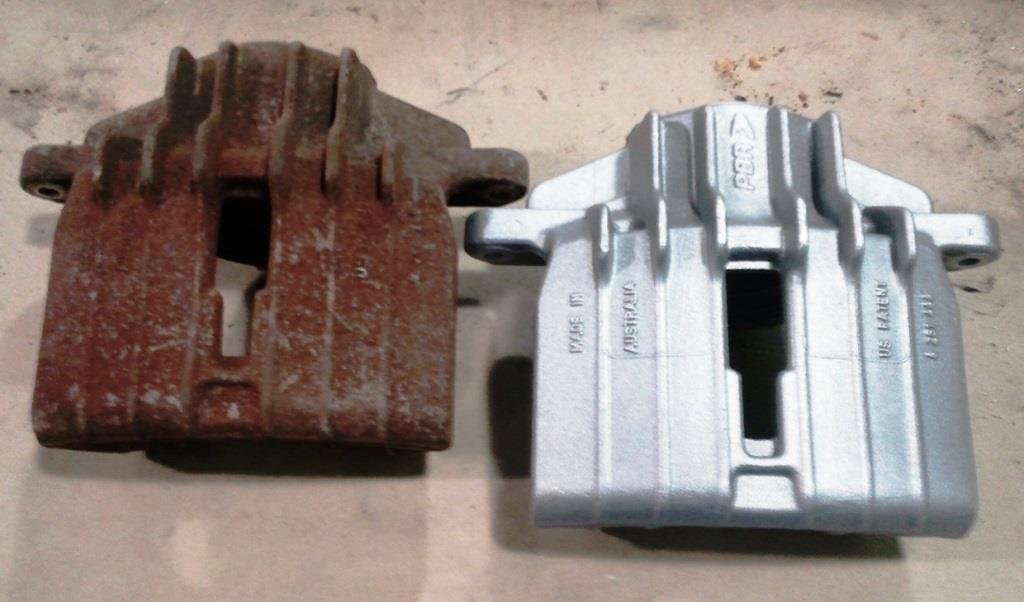

Preparation For Coating

In order for many materials to receive treatments and coatings, they must be shot blasted first to ensure that their surface is smooth and fully clean. This includes removing old paint and coatings from the surface which increases the durability of the new treatments, paints and coatings.

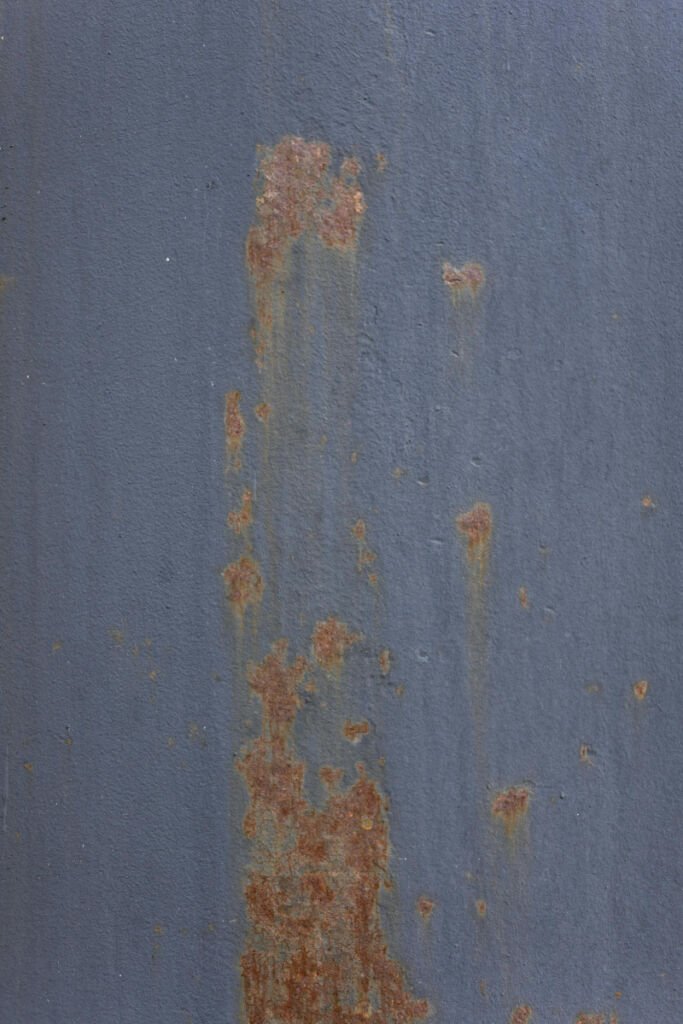

Remove Corrosion

Our shot blasting ensures that your metal is free from rust, pits and contaminants which causes your metal to be durable as well as being suitable to be treated. Removing corrosion also improves the visual appeal and performance of your materials.

Texture Enhancement

Shot blasting significantly smoothens the surface of your materials which enhances its texture. This can be beneficial for metals which become mechanical components as the refined texture helps to reduce friction. Another addition is that the smoothness can give the material a luxurious feel which is important for the materials that go on to be put into luxury goods.

Improved Aesthetic Appeal

Materials are always left extremely smooth and clean after being subject to our shot blasting procedures which gives them an aesthetic appeal. This is extremely important for materials which go on to be implemented into decorative fixtures, architectural elements, or high-end consumer products as their visual appeal is extremely important.

Benefits Of Shot Blasting

Reduced Environmental Impact

Our shot blasting services in Essex are excellent alternative methods when it comes to treating the surface of your materials compared to using hazardous and potent chemical solutions as shot blasting doesn’t emit any harmful chemicals which can harm the environment.

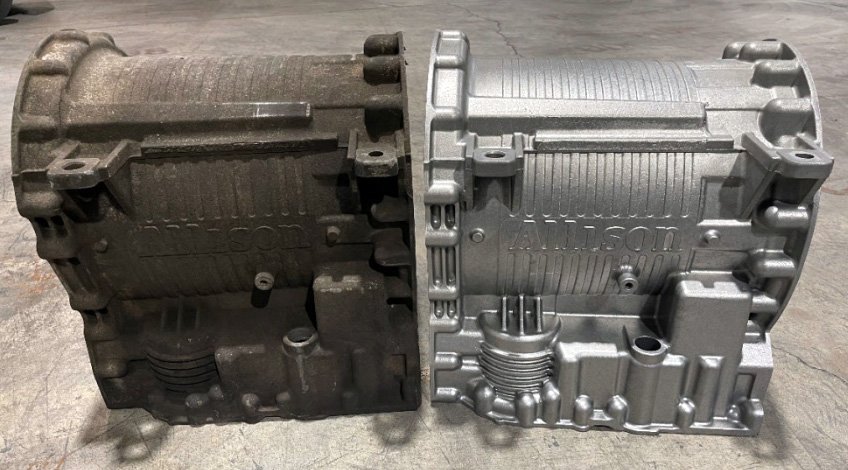

Improve Performance Of Components

Components can significantly increase in performance after being shot blasted as the surface of the materials become a lot smoother which reduces friction and subsequently leads to higher levels of efficiency and mechanical performance.

Cost Effective

Shot blasting completes the resurfacing process more efficiently than chemical treatments by requiring fewer and cheaper materials with reduced labour requirements which leads to reduced costs compared to chemical treatments.

Successful Outcomes Of Shot Blasting

What Happens If You Don't Shot Blast Your Materials?

If you don’t shot blast your materials, dirt, rust, and old coatings may stay on the surface which can weaken protective layers. This can cause them to peel off and fail quickly. Over time, untreated rust or corrosion can damage the material, making it weaker and shortening its lifespan. This can lead to the machines and materials needing more frequent maintenance services with higher costs for repairs.

Tailored To Suit Your Needs

Our team of experts tailor the needs of our shot blasting services to fully suit the needs of your materials and your desired outcomes to ensure that the performance and aesthetics of your materials are maximised to their fullest potential.

Why Work With Us?

Reliable Service

Our operating procedures ensure that your materials are consistently cut to fully suit your needs which ensures that your products are always ready to be used for the next stage in their journey.

Fast Turnaround

We aim to always deliver your shot blasted materials back to you soon after first receiving them to ensure that your engineering and manufacturing operations run as smoothly as possible.

Competitive On Costs

We pride ourselves on our industry competitive price point, ensuring that your needs can be catered for at as little cost as possible.

Request Your Free Quote

We pride ourselves on our bespoke one to one service which allows our specialists to fully understand your requirements in depth before tailoring your coating service to be a fast turnaround which fully suits your needs. Request Your Free Quote to understand how we can help you for the most competitive price!