Waterjet Cutting: Precision and Versatility with Premier Waterjet Cutting

Introduction to Waterjet Cutting

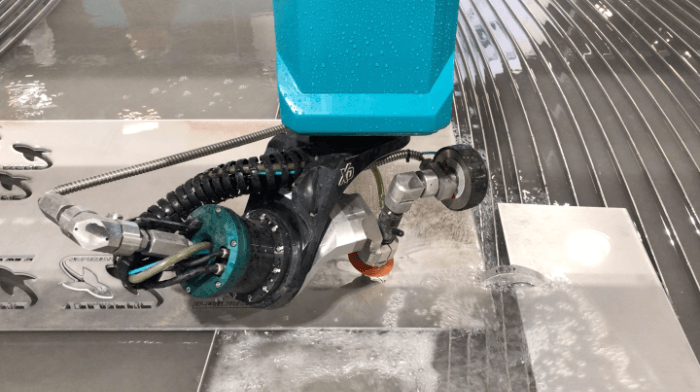

Waterjet cutting is a cutting-edge technology that utilizes a high-pressure stream of water, sometimes mixed with abrasive materials, to cut through a wide variety of materials with unmatched precision. At Premier Waterjet Cutting, based in Essex, we specialise in delivering high-quality waterjet cutting services across numerous industries. Our state-of-the-art technology allows us to achieve intricate designs and precise cuts without the heat distortion often associated with traditional cutting methods.

Applications of Waterjet Cutting

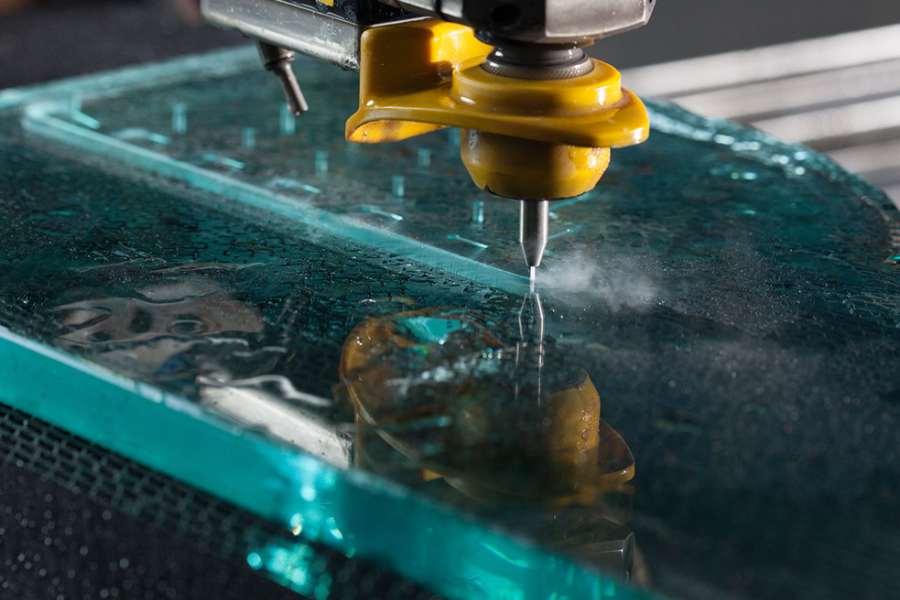

Waterjet cutting is an incredibly versatile process that can be applied to a wide range of materials, including metals, composites, stone, glass, and more. The technology is ideal for projects that require intricate detailing, such as in the automotive, aerospace, and architectural industries. Whether you’re working with robust materials like steel and titanium or more delicate substances like glass and ceramics, waterjet cutting ensures clean, accurate results every time.

- Metal Cutting Waterjet cutting is particularly effective for metals, from aluminium to stainless steel, providing clean cuts without leaving burrs or heat-affected zones. This makes it ideal for producing components that require high precision, such as those used in automotive and aerospace industries.

- Composite Materials When working with composite materials like carbon fibre or Kevlar, waterjet cutting offers the precision needed to avoid fraying or delamination, which can be a risk with other cutting methods. This technology is crucial for industries that rely on the strength and lightness of composite materials.

- Stone and Tile For intricate stonework or detailed tile cutting, waterjet technology allows for precise and creative designs without the risk of cracking or chipping, making it an excellent choice for architectural projects and custom interior designs.

- Glass Cutting Waterjet cutting is ideal for glass applications, providing smooth edges and detailed cuts that are essential in industries like architecture and design. However, it’s important to note that while waterjet can handle most types of glass, it is not suitable for toughened glass.

Industry Applications and Services

At Premier Waterjet Cutting, we serve a broad spectrum of industries, each with unique demands and standards. Our expertise in waterjet cutting is complemented by our commitment to quality and precision, making us a trusted partner across various sectors.

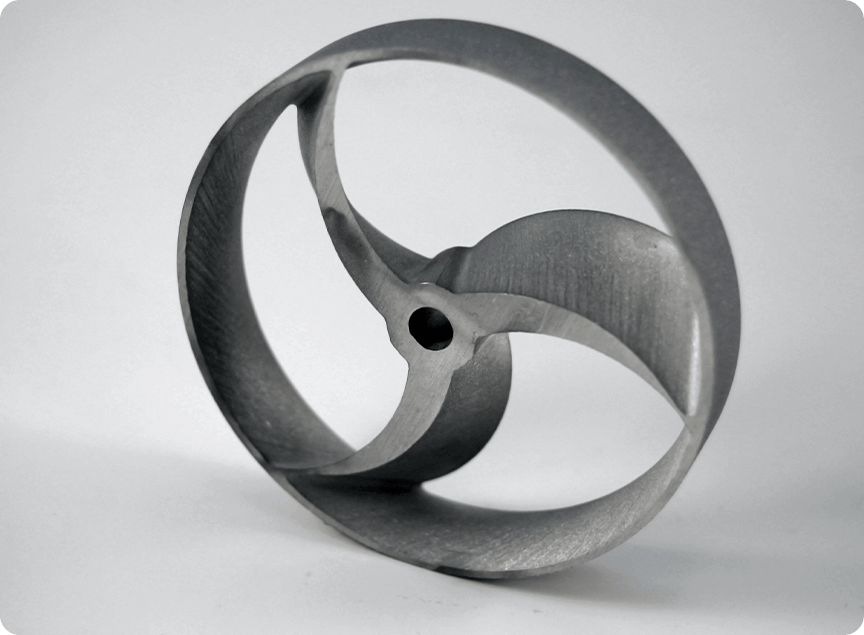

- Defence and MOD The defence sector demands precision, reliability, and the ability to work with a variety of materials under stringent specifications. Waterjet cutting is ideal for producing parts and components for military equipment, from armoured vehicles to aircraft. Our ability to work with tough materials like titanium and Inconel makes us well-suited to meet the high standards required by the Ministry of Defence (MOD).

- Automotive and Aerospace In both the automotive and aerospace industries, the need for lightweight yet strong components is critical. Waterjet cutting provides the precision required for these industries, whether it’s for prototypes or final components. The cold cutting process ensures that materials maintain their integrity without warping or changing properties due to heat.

- Architecture and Construction The architectural and construction sectors benefit from the versatility of waterjet cutting, allowing for the creation of complex designs and precise components. From cutting structural elements to detailed decorative pieces, waterjet cutting offers endless possibilities.

Why Choose Premier Waterjet Cutting?

Choosing Premier Waterjet Cutting means opting for precision, versatility, and a commitment to quality. Our cutting bed, which measures an impressive 4 metres by 2 metres, allows us to handle large projects efficiently. Our technology ensures that we can cut materials up to 200mm thick with a precision of +/- 0.01mm, meeting the most demanding specifications.

Moreover, our services are ISO 9001:2015 certified, ensuring that every project we undertake meets the highest standards of quality. Whether you’re a small business or a large corporation, our team is dedicated to providing excellent service and fast turnaround times.

Waterjet cutting offers unparalleled precision and versatility, making it the preferred choice across a wide range of industries. At Premier Waterjet Cutting in Essex, we are committed to delivering the highest quality cutting services, whether you’re working on a defence project, designing architectural elements, or producing aerospace components. Contact us today to discuss how we can bring your vision to life with our advanced waterjet cutting technology.

View our page on abrasive waterjet cutting.