Author Profile

- Neil JohnsManaging Director - Premier Waterjet Cutting

- Neil is the Managing Director of Premier Waterjet Cutting and has worked with some of the top engineering, construction and automotive companies throughout the UK for over 25 years.

Latest Posts

An Introduction To Waterjet Cutting

If you’re an engineer, fabricator, or material manager struggling with costly material distortion or inconsistent cuts, you’re not alone. Waterjet cutting is a non-thermal, highly precise method that offers clean, damage-free results for even the most complex materials, without heat damage or mechanical stress. In this 11-step guide, you’ll learn what waterjet cutting is, how it works, its advantages over laser and plasma cutting, and why it’s trusted in engineering, construction, joinery, and furniture manufacturing.

1. What Is Waterjet Cutting?

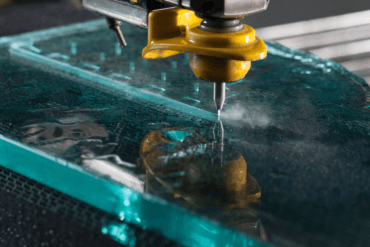

Waterjet cutting is the process of using an ultra-powerful jet of water to slice through materials. The interesting fact is that it’s a cold cutting technology, which means there’s no heat involved. That’s great news if you’re working with materials that can’t handle high temperatures or warping. There are actually two versions of this cutting method.

Pure waterjet cutting uses just water and is perfect for softer materials like rubber, foam and softer metals.

On the other hand, abrasive waterjet cutting mixes in metal particles (usually garnet) so the water solution is physically abrasive, allowing it to cut through harder and denser materials like dense steel, metal, stone, or composites.

In short both standard and abrasive waterjet cutting is a clean, precise and super versatile way to cut all sorts of things without the heat and hassle of traditional methods.

2. How Waterjet Cutting Works (Step-by-Step Process)

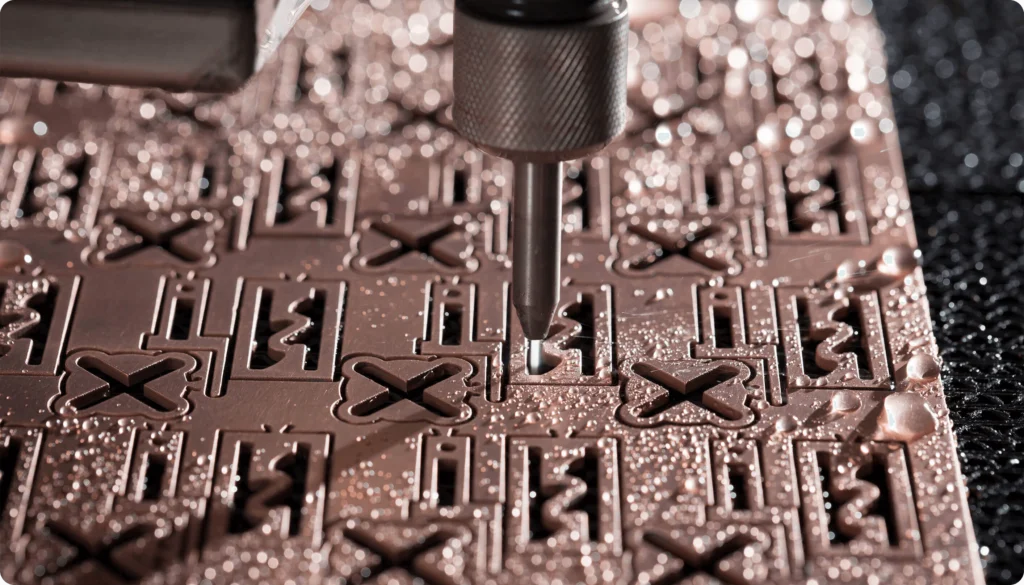

The waterjet cutting process starts with a CNC waterjet system, which combines computer-controlled precision with high-pressure water technology. CNC stands for Computer Numerical Control, meaning every cut is programmed and guided by software. This allows engineers and fabricators to create highly accurate, repeatable cuts—even for complex shapes or intricate patterns.

At the heart of the system is a high-pressure pump that boosts water pressure to anywhere from 30,000 to over 90,000 psi.

That water is then forced through a narrow nozzle, creating a focused stream powerful enough to cut through a wide range of materials. For abrasive waterjet cutting, tiny particles of garnet are added to the water stream just before it exits the nozzle. Together, the CNC control, high-pressure pump, nozzle, and abrasive media form a powerful, flexible tool capable of handling both delicate and heavy-duty cutting tasks. It’s a system designed for accuracy, efficiency while minimising material waste.

3. Waterjet Cutting vs. Other Methods (Laser, Plasma, Mechanical)

When comparing waterjet cutting to other methods like laser, plasma, or mechanical cutting, the biggest difference is that waterjet is a non-thermal process. That means it doesn’t use heat, which is a major advantage when you need to avoid material distortion or heat-affected zones.

In contrast, laser and plasma cutting relies on high temperatures to melt or burn through material, which can cause warping, rough edges, changes in the material’s properties and visual appearance.

In terms of edge finish and tolerances, waterjet cutting tends to produce cleaner, more precise cuts with minimal need for post-processing. Mechanical cutting methods, like sawing or milling also lack heat but come with their own issues like tool wear and limited flexibility with intricate shapes. When looking at waterjet cutting vs laser cutting or doing a comparison: waterjet vs plasma cutting, waterjet stands out for its versatility, accuracy, and ability to handle a wider variety of materials without compromising their integrity.

4. Key Benefits of Waterjet Cutting for Engineers and Fabricators

Waterjet cutting offers several key benefits that make it a go-to option for engineers and fabricators.

Preserved Structural Integrity

As a non-thermal cutting method, it eliminates heat-affected zones entirely, which helps preserve the structural integrity of the material.

High Precision

The process delivers high-precision cutting without heat, achieving tolerances as tight as ±0.01 mm with clean, burr-free edges that often require little to no finishing.

Highly Accurate

Waterjet cutting can cut with an accuracy of 0.05mm to 0.025mm. This is extremely beneficial for engineers who require materials to be cut with an extremely small tolerance.

Smooth Edge

Waterjet cutting delivers exceptionally smooth edges straight from the machine, eliminating the need for secondary finishing in most cases. Because there’s no heat involved, there’s no warping, burrs, or roughness, just clean and accurate cuts. This is especially useful for precision engineering tasks where edge quality matters as much as accuracy.

Increased Visual Appearance of Materials

The clean finish produced by waterjet cutting significantly improves the visual quality of the final part. There’s no heat discolouration or deformation, which means the original surface integrity and appearance are preserved. This is ideal for components that will be on display or used in architectural and bespoke applications where aesthetics are important.

Minimal Material Waste

Thanks to its narrow kerf width and precise cutting capabilities, waterjet cutting allows you to nest parts closely together, reducing raw material waste. This not only improves efficiency but also helps cut down on material costs, making the process more sustainable and cost-effective for high-precision projects.

5. What Materials Can Be Cut with a Waterjet?

One of the biggest advantages of waterjet cutting is its ability to handle a wide variety of materials with precision and consistency. Whether you’re working with soft, brittle, or extremely hard materials, a waterjet can usually cut through them cleanly and efficiently.

Common materials that are suitable for waterjet cutting include:

- Steel (mild, stainless, and tool steels)

- Aluminium and other non-ferrous metals

- Composites like carbon fibre and fibreglass

- Wood and MDF

- Glass (including laminated and tempered in some cases)

- Ceramics and tiles

- Plastics and rubber

- Stone, granite, and marble

This flexibility is due to the cold, high-pressure nature of the process, which avoids introducing heat that could damage delicate or heat-sensitive materials. The best materials for waterjet cutting are those where edge quality, surface finish, and dimensional accuracy matter.

In terms of waterjet cutting tolerances, high-quality systems can achieve precision down to ±0.01 mm, depending on material type and thickness. This level of control makes waterjet cutting suitable for everything from architectural panels to aerospace components, where both performance and finish are critical.

6. Common Industrial Applications of Waterjet Cutting

Industrial waterjet cutting can be used in many industries such as engineering, construction, artistic, bespoke joinery, carpentry and architecture, as well as in automotive sectors. Due to the nature of the cutting method being able to precisely cut metal to high levels of accuracy and precision, the cutting systems benefit industries where accurate and precise cutting is required such as in the industries below,

- Military And Defence

- Automotive

- Architectural

- Aerospace

- Medical

7. When to Choose Waterjet Cutting (and When Not To)

When To Choose Waterjet Cutting

Waterjet cutting is a great choice when you need clean, precise cuts without introducing heat into the material. It’s especially ideal for projects involving metals, composites, glass, or stone where maintaining the integrity and finish of the material is essential. If you’re working with intricate designs, tight tolerances, or heat-sensitive materials, a waterjet is often the most reliable solution. It’s also useful when cutting multiple types of materials in a single project, thanks to its versatility.

When Not To Choose Waterjet Cutting

That said, there are a few limitations of waterjet cutting to keep in mind. While it can handle thick materials that are thick, materials that are over 5-7 inches thick, depending on the setup, can cause the cutting speed to slow significantly with greater thickness. This can affect turnaround time and overall project efficiency. Also, the waterjet cutting cost is generally higher than methods like plasma or mechanical cutting, especially for basic shapes or high-volume, low-precision work. Yahoo Finance states that the annual growth of the purchasing of waterjet cutting machines is expected to grow by 3% per year which will reach 1.6 billion Dollars by 2030

If you’re unsure and don’t know which cutting method to use, think about your priorities. If you need high precision, a clean edge, and no heat distortion, waterjet is likely your best bet. But if speed or lower cost is more important and your tolerances are more forgiving, other methods might be more appropriate.

8. Environmental Advantages of Waterjet Cutting

As a socially responsible engineering company we take great pride in enforcing all of our environmental commitments by carrying out our processes, operations, purchasing and distribution in a way that best reduces environmental harm.

No Hazardous Fumes or Slag

Waterjet cutting is a cold process, meaning it doesn’t rely on heat to cut through materials. As a result, it produces no harmful fumes, smoke, or toxic gases unlike laser or plasma cutting, which can release hazardous substances, especially when working with coated or composite materials. There’s also no slag or molten waste, making for a cleaner and safer work environment.

Recyclable Abrasives

Most abrasive waterjet systems use garnet as the cutting medium, which is non-toxic and, in many cases, recyclable. Depending on the application, used garnet can be filtered, cleaned, and reused, reducing the need for constant raw material consumption and supporting more sustainable manufacturing practices.

Reduced Material Waste

Hydro-cutting is known for its precision. This high level of accuracy allows for tighter nesting of parts and smaller kerf widths, which leads to less scrap material overall. By maximising material use and reducing offcuts, waterjet cutting supports both cost-efficiency and environmental responsibility.

Lower Environmental Impact

When you consider the environmental impact of waterjet cutting compared to thermal methods, the benefits are clear. It’s a cleaner, quieter, and more resource-conscious approach, ideal for companies looking to reduce their environmental footprint without sacrificing cutting quality or performance.

9. Our Thoughts - Is Waterjet Cutting Right for Your Project?

Waterjet cutting is ideal if you need precise, clean cuts on a wide range of materials without heat damage. It’s perfect for projects where accuracy and finish quality matter most.

If speed or cost is your top priority, other methods might suit you better. Not sure? Get your free project assessment today and our team will help you to decide if waterjet cutting is the right choice for your project.

Have questions?

Get in touch!

Don't hesitate to contact us! We're happy to address any questions or concerns you

may have.